Core Technology

Core Technology

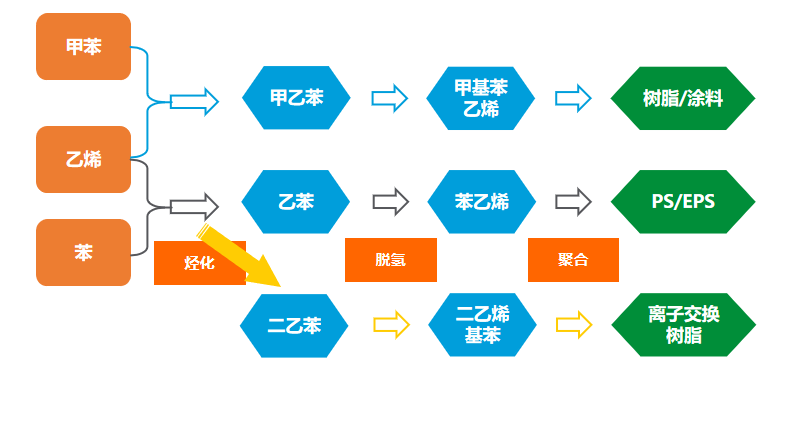

Complete process

Core Equipment

Catalyst

Ethylbenzene/styrene production technology

Summary:

Changzhou Ruihua Chemical Co., Ltd. has more than ten years of experience in ethylbenzene/styrene industrial engineering design, and successfully developed a complete set of ethylbenzene/styrene process technology at the beginning of the company's establishment. After nearly 10 years of technical improvement, the process package has reached the leading level in the latest operation of the device.

Classification:

Key words:

Detailed description

Changzhou Ruihua Chemical Co., Ltd. has more than ten years of experience in ethylbenzene/styrene industrial engineering design, and successfully developed a complete set of ethylbenzene/styrene process technology at the beginning of the company's establishment. After nearly 10 years of technical improvement, the process package has reached the leading level in the latest operation of the device.

In China, the performance of ethylbenzene/styrene industry covers East China and North China, with more than 10 sets of devices in operation and projects under construction. The maximum production capacity reaches 350000 tons/year (in terms of styrene), and the design capacity can reach 600000 tons/year. Has been granted a number of patents, ZL 200710043304.6, ZL 200810042115.1, ZL 200810042116.6, ZL 201110135700.8, ZL 201110135696.5, ZL 201110162992.4, ZL 201110162995.8, ZL201920558075.X, ZL 202020799131.1, ZL201710293859.X

Moreover, we have maintained long-term and close technical cooperation with many engineering design institutes and catalyst suppliers at home and abroad. To ensure that the process technology is mature and reliable and in a constantly updated state, to maximize the benefits to the user.

Process development direction-energy saving and consumption reduction

● Ethylene Section-Improvement of ethylene transportation, handling, storage, feeding and cold recovery systems.

● Optimization of feedstock ratio, utilization of steam between reactor sections, improvement of design and parameters of each separation column in ethylbenzene partial-alkylation reaction.

● Styrene part-reduction of pressure drop in feed and reaction system, improvement of arrangement and setting parameters of heat exchangers, application of steam recovery, renewal of design of separation tower and improvement of tail gas recovery.

Key Patent Technology

The ethylbenzene dehydrogenation reactor adopts the mode of axial radial flow of materials in the reactor. The uniform distribution of the fluid adopts a double-curved cone, which eliminates the pressure drop of the perforated plate through the hole, rationally uses the radial flow technology, optimizes the design of the collection and shunt flow channel, and makes the pressure drop of the reactor meet the requirements of the negative pressure reaction.

This design has the following advantages:

• Catalyst bed pressure drop is minimized.

● The reaction materials are fully mixed in the reactor, and the process meets the requirements of reaction kinetics.

● There is no coking phenomenon in operation to ensure normal, stable and long-term operation of production.

● High yield of styrene, good selectivity, leading production indicators.

Recommended Information

0nline message

Contact us

5/F, Block A, Building 1, Chuangyan Port, Science and Education City, Wujin District, Changzhou City, Jiangsu Province

Copyright© 2024 Ruihua Chemical