Core Technology

Core Technology

Complete process

Core Equipment

Catalyst

ETHYLBENZENE/STYRENE KEY EQUIPMENT MANUFACTURING

Summary:

In China, the performance of ethylbenzene/styrene industry covers East China and North China, with more than 10 sets of devices in operation and projects under construction. The maximum production capacity reaches 350000 tons/year (in terms of styrene), and the design capacity can reach 600000 tons/year. It is the only Chinese patent dealer for the design of the largest capacity ethylbenzene/styrene plant.

Classification:

Key words:

Detailed description

Overview

Changzhou Ruikai Chemical Equipment Co., Ltd. is located in Rulin Town, Jintan District, Changzhou. It has A2 pressure vessel manufacturing qualification and is wholly owned by its parent company, Changzhou Ruihua Chemical Engineering Technology Co., Ltd. Specializing in ethylene storage and transportation, aromatic alkylation (ethylbenzene/p-xylene), aromatic dehydrogenation (styrene/methylstyrene/divinylbenzene), expandable polystyrene (EPS), isobutane normal structure, butane maleic anhydride, indirect oxidation propylene oxide (ethylbenzene, cumene, isobutane), hydrogenation (crude benzene, benzene, maleic anhydride) and a series of chemical core equipment research and development, design and manufacturing business.

Our company has obtained a number of authorized patents, and used in the production of manufacturing technology:

ZL2018222518774, ZL2019205302171, ZL2019208220309,ZL2019208495000.0,ZL201920849559X, ZL2019209609761.1,ZL2019209842770, ZL201921001494X, ZL2019209921147, ZL2019209969432,ZL2015103015639,ZL201905536766 , ZL2020225021084 , ZL2020227234920

Since its establishment in 2014, our company has manufactured hundreds of equipment for the manufacture of products in the chemical industry in the past 6 years.

Overview

In China, the performance of ethylbenzene/styrene industry covers East China and North China, with more than 10 sets of devices in operation and projects under construction. The maximum production capacity reaches 350000 tons/year (in terms of styrene), and the design capacity can reach 600000 tons/year.

Moreover, we have maintained long-term and close technical cooperation with many engineering design institutes and catalyst suppliers at home and abroad. To ensure that the process technology is mature and reliable and in a constantly updated state, to maximize the benefits to the user.

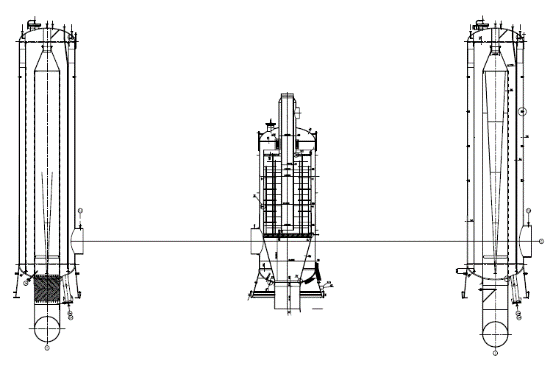

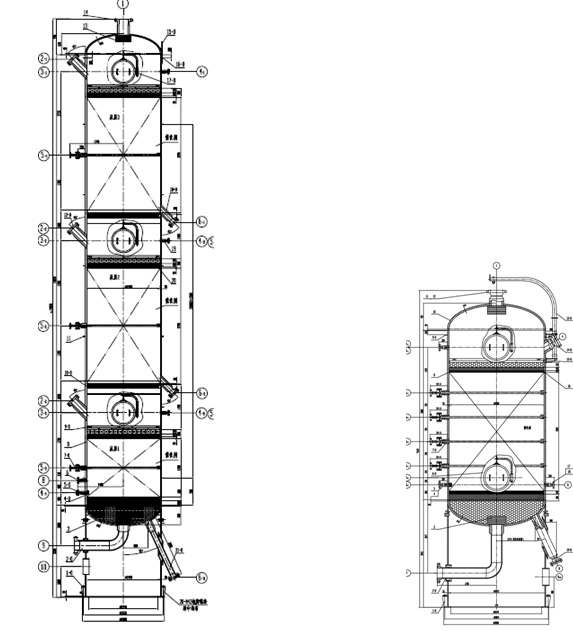

Key patent technology: ethylbenzene dehydrogenation reactor adopts the way of axial radial flow of materials in the reactor. The uniform distribution of the fluid adopts a double-curved cone, which eliminates the pressure drop of the perforated plate through the hole, rationally uses the radial flow technology, optimizes the design of the collection and shunt flow channel, and makes the pressure drop of the reactor meet the requirements of the negative pressure reaction.

Ethylbenzene dehydrogenation high-temperature heat exchanger was recognized by Changzhou's first (set) of major equipment and key components in 2017.

Key Equipment

The structure of some key equipment is shown in the following table:

| Serial Number | Equipment Name | Main material of equipment | Container Category | Remarks |

| 1 | First dehydrogenation reactor | 304H | Out of class | |

| 2 | Second dehydrogenation reactor | 304H | Out of class | |

| 3 | Intermediate reheater | 304H | Out of class | |

| 4 | Superheater | 304H | Out of class | |

| 5 | Second Rough Column Reboiler | Q345R | Out of class |

| Serial Number | Equipment Name | Main material of equipment | Category |

| 1 | reverse alkylation reactor | Q345R | III |

| 2 | Protecting the reactor | Q345R | III |

| 3 | hydrocarbonylation reactor | Q345R | III |

Application example

Ruikai chemical equipment has been successfully industrialized and transformed more than a dozen sets from 60000 tons to 350000 tons of ethylbenzene/styrene plant.

Major customers in recent years:

| Serial Number | Project Name | Delivery time | Remarks |

| 1 | Xinyang Technology Group Co., Ltd. 600000 tons/year ethylbenzene and 300000 tons/year styrene combined plant | 2015.08 | |

| 2 | Ningbo Keyuan Plastic Co., Ltd. 200000 Tons/Year Ethylbenzene-Styrene Reconstruction and Expansion Plant | 2016.05 | |

| 3 | Dongming CITIC Ruihua New Materials Co., Ltd. 50000 tons/year methyl styrene plant | 2017.06 | |

| 4 | Anhui Haoyuan Chemical Group Co., Ltd. 260000 tons/year styrene combined plant | 2017.12 | |

| 5 | Liaoning Baolai Chemical Co., Ltd. 350000 tons/year styrene plant | 2018.10 | |

| 6 | Hebei Shengteng Chemical Co., Ltd. 60000 tons/year styrene plant | 2018.09 | |

| 7 | Ningbo Huatai Shengfu Polymeric Material Co., Ltd. 300000 tons/year styrene plant (actual 400000 tons/year styrene) | 2019.12 | |

| 8 | Anhui Jiaxi New Material Co., Ltd. C4/C5, C9 Comprehensive Utilization and Styrene Project | 2020.05 | |

| 9 | Sinochem Hongrun Petrochemical Co., Ltd. 120000 tons/year styrene plant | 2020.07 | |

| 10 | Tangshan Xuyang Aromatic Products Co., Ltd. 300000 tons/year styrene plant | 2020.07 |

Recommended Information

Previous

Previous

0nline message

Contact us

5/F, Block A, Building 1, Chuangyan Port, Science and Education City, Wujin District, Changzhou City, Jiangsu Province

Copyright© 2024 Ruihua Chemical