Core Technology

Core Technology

Complete process

Core Equipment

Catalyst

Manufacture of key equipment for propylene oxide/styrene co-production technology

Summary:

Propylene oxide is the third largest propylene derivative after polypropylene and acrylonitrile. It is mainly used in the production of polyether, propylene glycol, etc. Its derivatives are widely used in automobile, construction, food, tobacco, medicine and cosmetics industries. Nearly 100 kinds of downstream products have been produced, which are important raw materials for fine chemical products.

Classification:

Key words:

Detailed description

Overview

Propylene oxide is the third largest propylene derivative after polypropylene and acrylonitrile. It is mainly used in the production of polyether, propylene glycol, etc. Its derivatives are widely used in automobile, construction, food, tobacco, medicine and cosmetics industries. Nearly 100 kinds of downstream products have been produced, which are important raw materials for fine chemical products.

Industrial propylene oxide production technology mainly has chlorohydrin method and indirect oxidation method. The production of propylene oxide by chlorohydrin method is characterized by relatively short process, mature process and low construction investment. However, a large amount of wastewater containing calcium chloride will be produced in the process of producing propylene oxide by chlorohydrin method, and the environmental pollution is very serious. Therefore, China has stopped the approval of new chlorohydrin propylene oxide plant since 2011.

At present, all domestic propylene oxide units using indirect oxidation process adopt foreign technology. Changzhou Ruihua Chemical has incorporated indirect oxidation propylene oxide technology into the scope of research and development since its establishment. After five years of development, it has successfully developed complete sets of process technologies for propylene oxide/styrene co-production (PO/SM) and propylene oxide/styrene co-production (PO/AMS).

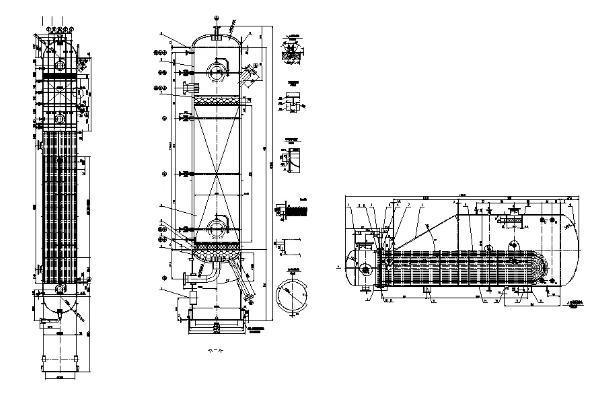

Key Equipment

The key equipment of the process is shown in the figure, as shown in the table below:

| Serial Number | Equipment Name | Main material of equipment | Container Category | ||

| 1 | hydrocarbonylation reactor | Q345R,16Mn Ⅲ | III | ||

| 2 | reverse alkylation reactor | Q345R,16Mn Ⅲ | III | ||

| 3 | hydrogenation reactor | Q345R,16Mn Ⅲ | III | ||

| 4 | cyclization protection reactor | S31603 | III | ||

| 5 | epoxidation reactor | Q345R 16Mn Ⅲ | Q345R S31603 16Mn Ⅲ (Surfacing S31603) | III | |

| 6 | Protecting the reactor | Q345R,16Mn Ⅲ | III | ||

| 7 | hydrogenation protection reactor | Q345R,16Mn Ⅲ | III | ||

| 8 | falling film crystallizer | S30408 S30408 II | II | ||

| 9 | Scraper evaporator | S30408 | I | ||

| 10 | dehydration reactor | 15CrMoR,15CrMo II | |||

| 11 | hydrocarbonylation reactor | Q345R,16Mn Ⅲ | III | ||

| 12 | reverse alkylation reactor | Q345R,16Mn Ⅲ | III | ||

| 13 | hydrogenation reactor | Q345R,16Mn Ⅲ | III | ||

| 14 | Phenylethyl alcohol vaporizer | Q345R,16MnII | II | ||

| 15 | cyclization protection reactor | S31603 | III | ||

| 16 | epoxidation reactor | Q345R 16Mn Ⅲ | Q345R S31603 16Mn Ⅲ (Surfacing S31603) | III | |

| 17 | Protecting the reactor | Q345R,16Mn Ⅲ | III | ||

| 18 | hydrogenation protection reactor | Q345R,16Mn Ⅲ | III | ||

| 19 | falling film crystallizer | S30408 S30408 II | II | ||

| 20 | three-effect evaporator | TA2 | I | ||

| 21 | peroxide decomposer | TA2 | S30408 Forging S30408,TA2 | II | |

| 22 | Epoxidizing alkaline washing tank | Q345R 16Mn Ⅱ | II | ||

| 23 | Scraper evaporator | S30408 | I | ||

| 24 | dehydration reactor | 15CrMoR,15CrMo II | |||

| 25 | circulating ethylbenzene preheater | Q345R,20,20 Ⅱ | Q345R,20,16Mn II | ||

Application example

The raw material ethylbenzene for POSM process must be alkylated with vinylbenzene, and the purity of ethylbenzene is> = 99.8. Raw material propylene shall meet the requirements of GB 7716-2002 for superior products.

Major customers in recent years:

| Serial Number | Project Name | Delivery time | Remarks |

| 1 | Dongming CITIC Ruihua New Materials Co., Ltd. 200000 tons/year styrene co-production 80000 tons/year propylene oxide plant | 2019.12 | |

| 2 | Zhejiang Petrochemical Co., Ltd. 600000 tons/year styrene co-production 270000 tons/year propylene oxide plant | In manufacturing |

Recommended Information

0nline message

Contact us

5/F, Block A, Building 1, Chuangyan Port, Science and Education City, Wujin District, Changzhou City, Jiangsu Province

Copyright© 2024 Ruihua Chemical