Core Technology

Core Technology

Complete process

Core Equipment

Catalyst

Low Carbon Olefin Production Technology (RHMTP)

Summary:

Maleic anhydride is one of the world's three major anhydride raw materials (acetic anhydride, maleic anhydride, phthalic anhydride), and its downstream products have a wide range of development and application prospects, can be used in synthetic resins, coatings, pesticides, lubricating oil additives, pharmaceuticals, paper treatment agents, food additives, stabilizers and so on.

Classification:

Key words:

Detailed description

Application areas

Maleic anhydride is one of the world's three major anhydride raw materials (acetic anhydride, maleic anhydride, phthalic anhydride), and its downstream products have a wide range of development and application prospects, can be used in synthetic resins, coatings, pesticides, lubricating oil additives, pharmaceuticals, paper treatment agents, food additives, stabilizers and so on.

At present, the production technology of maleic anhydride mainly includes butane process and benzene process. At present, the production capacity of maleic anhydride in China is mostly the traditional benzene process, but with the promotion of the utilization of carbon four resources, the butane process maleic anhydride device has gradually formed a scale.

Ruihua maleic anhydride technology uses n-butane as raw material and reacts with air to produce maleic anhydride. The oxidation reaction is a strong exothermic reaction, and the reaction heat needs to be removed during the reaction process, so the maleic anhydride device can output a large amount of steam. Because of this feature, the maleic anhydride device is suitable for joint setting with some high steam consumption devices, such as ethylbenzene styrene device, which can achieve the purpose of steam complementarity and improve the economy of the two sets of devices.

Compared with the traditional benzene maleic anhydride technology, RHMA technology can completely eliminate the pollution of benzene to the environment, high yield of maleic anhydride, low energy consumption, high amount of external steam, long operating cycle of the device.

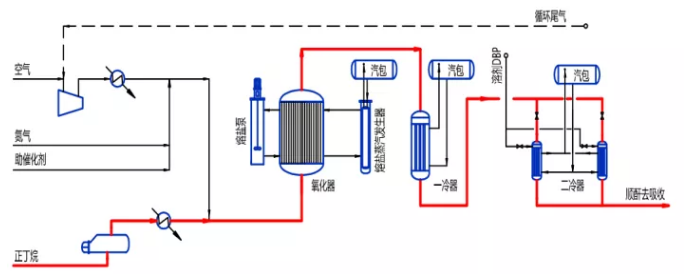

Process

The butane is evaporated and mixed with air before entering the oxidation reactor. The oxidation reactor is a tubular fixed bed reaction type. The catalyst is placed in the reaction tube. Butane and air react to generate maleic anhydride after contacting with the catalyst. At the same time, a large amount of reaction heat is released and removed by the molten salt on the shell side. The heated molten salt is returned to the reactor after being used to produce steam. In the oxidation reactor, the single-pass conversion of butane can reach 82 ~ 85%, and the weight yield of maleic anhydride is 97~103%.

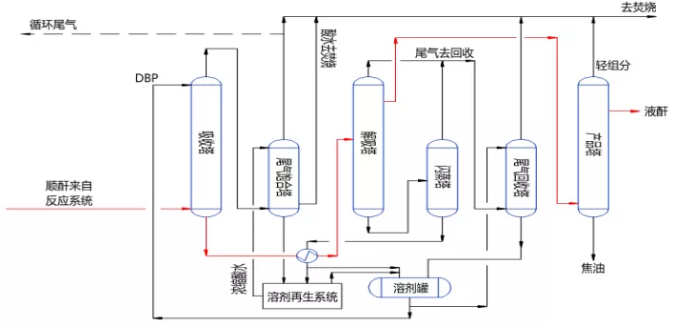

After the reaction, the gas enters the post-treatment system after two-stage cooling. The post-treatment system of Ruihua maleic anhydride technology adopts solvent absorption process, and the solvent is dibutyl phthalate. The reaction gas after absorption, desorption, purification and other operations to obtain the product maleic anhydride, purity of 99.5%.

Feed requirements

The purity of n-butane used for the production of maleic anhydride should be> = 99%, the total olefin content <= 0.3%, and the sulfur and chlorine content <= 10ppm.

n-butane can be separated from C4 materials containing n-butane, such as mixed butane and ether-based carbon tetra, or it can be used after isobutane is made into n-butane by isobutane normal structure process.

Recommended Information

0nline message

Contact us

5/F, Block A, Building 1, Chuangyan Port, Science and Education City, Wujin District, Changzhou City, Jiangsu Province

Copyright© 2024 Ruihua Chemical