Core Technology

Core Technology

Complete process

Core Equipment

Catalyst

Maleic Anhydride Production Technology Key Equipment Manufacturing

Summary:

Maleic anhydride is one of the world's three major anhydride raw materials (acetic anhydride, maleic anhydride, phthalic anhydride), and its downstream products have a wide range of development and application prospects, can be used in synthetic resins, coatings, pesticides, lubricating oil additives, pharmaceuticals, paper treatment agents, food additives, stabilizers and so on.

Classification:

Key words:

Detailed description

Overview

Maleic anhydride is one of the world's three major anhydride raw materials (acetic anhydride, maleic anhydride, phthalic anhydride), and its downstream products have a wide range of development and application prospects, can be used in synthetic resins, coatings, pesticides, lubricating oil additives, pharmaceuticals, paper treatment agents, food additives, stabilizers and so on.

At present, the production technology of maleic anhydride mainly includes butane process and benzene process. At present, the production capacity of maleic anhydride in China is mostly the traditional benzene process, but with the promotion of the utilization of carbon four resources, the butane process maleic anhydride device has gradually formed a scale.

Ruihua maleic anhydride technology uses n-butane as raw material and reacts with air to produce maleic anhydride. The oxidation reaction is a strong exothermic reaction, and the reaction heat needs to be removed during the reaction process, so the maleic anhydride device can output a large amount of steam. Because of this feature, the maleic anhydride device is suitable for joint setting with some high steam consumption devices, such as ethylbenzene styrene device, which can achieve the purpose of steam complementarity and improve the economy of the two sets of devices.

Compared with the traditional benzene maleic anhydride technology, RHMA technology can completely eliminate the pollution of benzene to the environment, high yield of maleic anhydride, low energy consumption, high amount of external steam, long operating cycle of the device.

Key Equipment

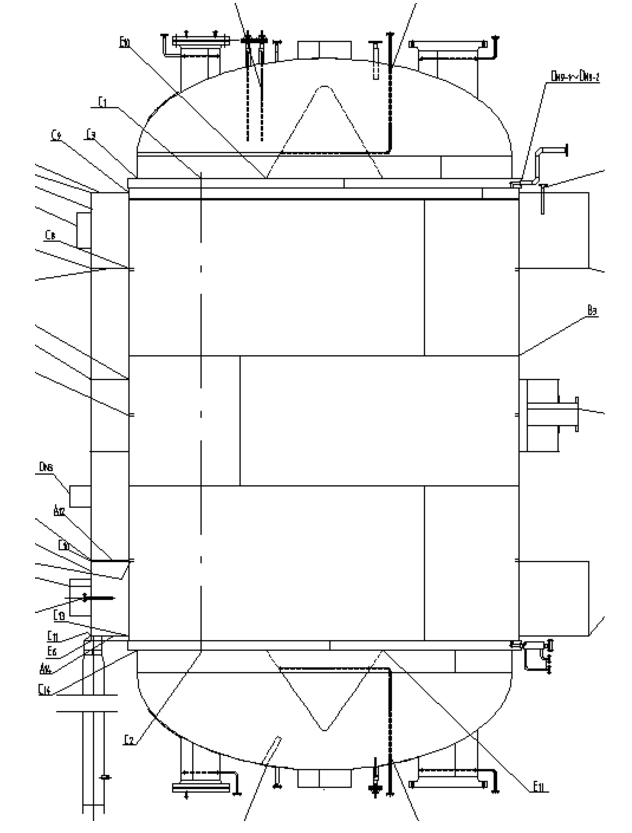

The oxidation reactor developed by Ruikai chemical equipment aims at the problems existing in the axial tubular fixed bed reactor used for maleic anhydride production in industry at present, and proposes a new type of reactor with a multi-layer gas distributor with a central guide cone or/and an outlet rectifier and vortex breaker with a central guide cone to form a uniform flow field and eliminate the reflux zone, thus solving the long-time retention of reactants and reaction products, the problem of undesirable side reactions is eliminated, while the safety of the reactor is improved and the energy saving effect is improved.

See the following for the equipment:

Application example

The oxidation reactor is installed on the site of the n-butane deep processing industry chain project of Luoyang Refining and Chemical Jiuyuan Petrochemical Co., Ltd. Its supporting supply equipment: molten salt cooler, electric heater, molten salt pump, molten salt valve and blasting disc are all installed and delivered. In September 2020, the unit will be officially put into operation. According to the calculation of relevant personnel in the process department, the reaction yield of maleic anhydride will be significantly improved, the unit consumption of butane, a raw material for producing maleic anhydride, decreased from 1.1 to 1.05t butane/t maleic anhydride. The 40000-ton/year maleic anhydride plant of the project is currently operating stably, and the annual raw material cost alone will be saved by ~ 8 million yuan. At the same time, the "tail burning phenomenon" of the oxidizer did not occur again ".

Recommended Information

0nline message

Contact us

5/F, Block A, Building 1, Chuangyan Port, Science and Education City, Wujin District, Changzhou City, Jiangsu Province

Copyright© 2024 Ruihua Chemical