Core Technology

Core Technology

Complete process

Core Equipment

Catalyst

Capacity expansion technology for dry gas production of ethylbenzene

Summary:

Up to now, there are some plants in China that have applied dry gas to ethylbenzene/styrene technology, mainly 6 to 80000 tons of styrene per year, distributed in PetroChina, Sinopec, China Chemical and various private enterprises. The dry gas method was used as raw material to produce ethylbenzene, which solved the problem of dry gas resource utilization at that time. However, in the actual production over the years, the vast majority of dry gas to ethylbenzene/styrene plant load can not reach the design value, not to mention the increase in styrene prices to increase capacity to increase efficiency.

Classification:

Key words:

Detailed description

Application areas

Up to now, there are some plants in China that have applied dry gas to ethylbenzene/styrene technology, mainly 6 to 80000 tons of styrene per year, distributed in PetroChina, Sinopec, China Chemical and various private enterprises. The dry gas method was used as raw material to produce ethylbenzene, which solved the problem of dry gas resource utilization at that time. However, in the actual production over the years, the vast majority of dry gas to ethylbenzene/styrene plant load can not reach the design value, not to mention the increase in styrene prices to increase capacity to increase efficiency.

The main reasons are:

1. The ethylene content in the dry gas is low, and under the restriction of the dry gas volume, it cannot meet the requirements of the ethylbenzene production process index.

The ethylene content in the dry gas basically meets the process requirements, but the total amount of dry gas is very low, resulting in insufficient supply of raw materials to meet the production of ethylbenzene.

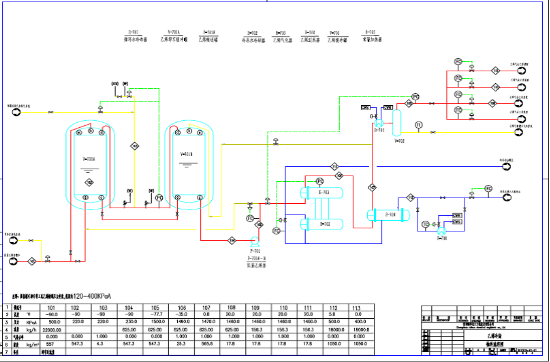

Process

In order to achieve the production increase target of the unit, a low-temperature ethylene storage tank system is set up as a supplement to the ethylene source in the dry gas. Low-temperature ethylene is transported by tanker, and the ethylene tank adopts mature low-temperature tank technology. The output of ethylene is combined with the need of cold capacity of styrene plant, and the cold capacity is recovered by low-temperature ethylene cold capacity recovery process. In addition, several low-pressure steam is recovered by steam jet heat pump to produce suitable medium-pressure steam for utilization.

The low-temperature ethylene from the tank car is pressurized by the self-contained gasification system or the ethylene gasification system in the tank farm, and the low-temperature ethylene is pressurized into the V-701A of the unloading ethylene tank. After the ethylene liquid in the tank is pressurized by the low-temperature ethylene pump, it enters the ethylene buffer tank after being gasified and overheated, and finally enters the ethylbenzene unit hydrocarbon reactor.

Technical advantages

● The structure of the process device is simple and can be operated under various working conditions through multi-means adjustment.

● All the cold energy of low-temperature ethylene is taken out and used in the process production unit and storage unit to reduce the ice machine power consumption.

● The design and manufacture of core equipment fully consider the requirements of physical properties and working conditions, and the process operation is stable.

● No "three wastes" discharge.

Recommended Information

0nline message

Contact us

5/F, Block A, Building 1, Chuangyan Port, Science and Education City, Wujin District, Changzhou City, Jiangsu Province

Copyright© 2024 Ruihua Chemical