Core Technology

Core Technology

Complete process

Core Equipment

Catalyst

Acetophenone/dimethyl adipate hydrogenation catalyst

Summary:

Changzhou Ruihua's hydrogenation catalyst (KAH) has the characteristics of high conversion rate, good selectivity, high mechanical strength and long life, and can be used as a general hydrogenation catalyst.

Classification:

Key words:

Detailed description

Overview

Changzhou Ruihua's hydrogenation catalyst (KAH) has the characteristics of high conversion rate, good selectivity, high mechanical strength and long life, and can be used as a general hydrogenation catalyst.

Hydrogenation of acetophenone can produce phenethyl alcohol, which in turn is dehydrated to produce styrene, while hydrogenation of dimethyl adipate can produce hexanediol. The KAH type catalyst produced by Changzhou Ruihua shows the characteristics of high activity and high selectivity when it is applied to the hydrogenation of acetophenone to produce phenethyl alcohol and the hydrogenation of dimethyl adipate to produce hexylene glycol.

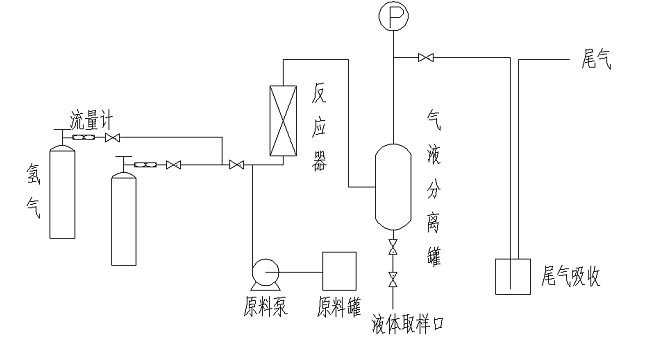

Process

The hydrogenation of acetophenone is carried out in an adiabatic fixed bed reactor, and acetophenone and hydrogen are respectively metered by a metering pump and a mass flow meter in a certain proportion and then enter the catalyst bed together. In the reactor, acetophenone is hydrogenated under the action of KAH catalyst, and the product phenethyl alcohol and by-product ethylbenzene are produced with high selectivity. The conversion rate of acetophenone and the selectivity of phenethyl alcohol can reach more than 99%.

The hydrogenation of dimethyl adipate was carried out in the same pilot plant. Dimethyl adipate and hydrogen enter the reactor together after metering by a metering pump and a mass flow meter respectively according to a certain proportion. The conversion of dimethyl adipate and the selectivity of hexanediol can reach more than 99%.

After 2000 hours of life test, the activity of the KAH catalyst of Ruihua did not decrease significantly.

Recommended Information

Next

Next

0nline message

Contact us

5/F, Block A, Building 1, Chuangyan Port, Science and Education City, Wujin District, Changzhou City, Jiangsu Province

Copyright© 2024 Ruihua Chemical