Core Technology

Core Technology

Complete process

Core Equipment

Catalyst

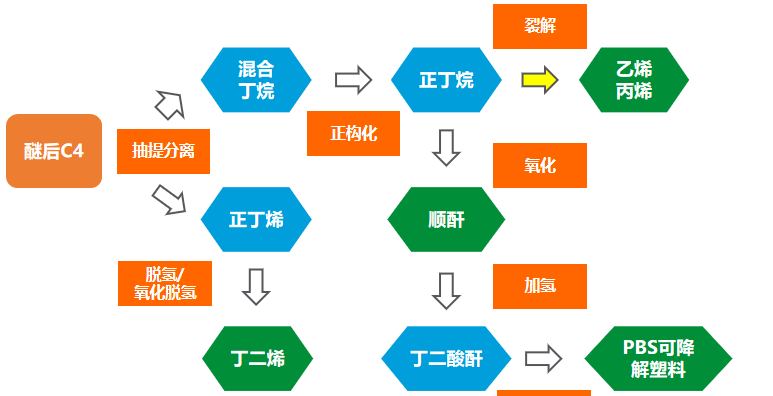

Low Carbon Olefin Production Technology (RHMTP)

Summary:

The production technology of Ruihua C4 cracking plant transformed into methanol to propylene can be used to produce propylene, ethylene, liquefied petroleum gas and aromatic gasoline. This technology is highly adaptable to the market, and the product plan can be adjusted according to demand, making it very competitive in small and medium-sized industrial applications.

Classification:

Key words:

Detailed description

Application areas

The production technology of Ruihua C4 cracking plant transformed into methanol to propylene can be used to produce propylene, ethylene, liquefied petroleum gas and aromatic gasoline. This technology is highly adaptable to the market, and the product plan can be adjusted according to demand, making it very competitive in small and medium-sized industrial applications.

The technical raw material can start from methanol or from dimethyl ether. When the starting material is methanol, two reactors are required. One is a pre-reactor for the reaction of methanol to produce dimethyl ether, and the other is a further reaction of the produced dimethyl ether to produce propylene-based low-carbon olefins. When the starting material is dimethyl ether, only one reactor for generating low-carbon olefins mainly composed of propylene from dimethyl ether is required.

This technology is used in the transformation of the old device (carbon four cracking), which can make use of more original devices, save investment for enterprises and create more profits.

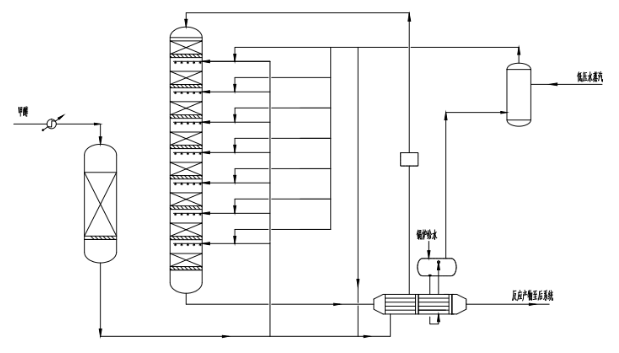

Process

The reaction with methanol as raw material first generates dimethyl ether through a fixed bed reactor. The generated dimethyl ether is divided into two streams and enters the multi-stage fixed bed reactor respectively. One stream of main material enters the first bed layer from the top of the reactor after being mixed with low pressure steam, and the other stream is divided into seven streams and enters the second to eighth beds from the seven stages of the reactor respectively after being mixed with low pressure steam. The reactor discharge is recovered by quenching, absorption and stabilization, and the products propylene, ethylene, liquefied petroleum gas and aromatic gasoline are separated.

The product propylene in this process is polymer grade, ethylene can reach polymer grade, liquefied gas (mainly carbon four), aromatic gasoline (can be used for gasoline blending components to improve octane number). According to different recycling processes, the yield of propylene can reach up to 25%, and the yield of ethylene can reach up to 8%.

Feed requirements

The raw material methanol shall meet the requirements of GB 338-2011.

Recommended Information

0nline message

Contact us

5/F, Block A, Building 1, Chuangyan Port, Science and Education City, Wujin District, Changzhou City, Jiangsu Province

Copyright© 2024 Ruihua Chemical