Core Technology

Core Technology

Complete process

Core Equipment

Catalyst

Butadiene energy-saving production technology

Summary:

The position of butadiene in petrochemical olefin raw materials is second only to ethylene and propylene, and butadiene is the main raw material for the production of synthetic rubber (styrene butadiene rubber, butadiene rubber, nitrile rubber, chloroprene rubber). With the development of styrene plastics, the use of styrene and butadiene copolymer, the production of a wide range of resins (such as ABS resin, SBS resin, BS resin, MBS resin), so that butadiene in the resin production gradually occupy an important position. In addition, butadiene is still used in the production of 1,4-butanediol (engineering plastics), dicarbonitrile (nylon 66 monomer), sulfolane, tetrahydrofuran, etc., and is also an important basic chemical raw material.

Classification:

Key words:

Detailed description

Application areas

The position of butadiene in petrochemical olefin raw materials is second only to ethylene and propylene, and butadiene is the main raw material for the production of synthetic rubber (styrene butadiene rubber, butadiene rubber, nitrile rubber, chloroprene rubber). With the development of styrene plastics, the use of styrene and butadiene copolymer, the production of a wide range of resins (such as ABS resin, SBS resin, BS resin, MBS resin), so that butadiene in the resin production gradually occupy an important position. In addition, butadiene is still used in the production of 1,4-butanediol (engineering plastics), dicarbonitrile (nylon 66 monomer), sulfolane, tetrahydrofuran, etc., and is also an important basic chemical raw material.

The present technology is used for the oxidative dehydrogenation of butene to produce butadiene. In the whole process, a series of energy-saving technologies are applied to ensure high conversion rate and high selectivity, while reducing production energy consumption.

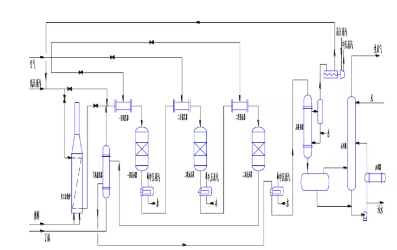

Process flow

This technology adopts multi-stage insulation fixed bed reactor process, the use of waste heat boiler between the sections, the use of inlet and outlet heat exchanger, after heat exchanger and compression heat pump and other combined equipment, for butene oxidation dehydrogenation process of butadiene energy saving.

Ruihua Chemical also uses a special feed distribution method to feed oxygen-containing gas, butene and water vapor into each section of the reactor according to a certain ratio. The product selectivity and catalyst life can be greatly improved.

In addition, Ruihua Chemical has developed a catalyst more suitable for the oxidative dehydrogenation of butene, which has been verified to meet the requirements of oxidative dehydrogenation and has excellent process indicators.

Technical advantages

The feed temperature for the oxidative dehydrogenation of butene is 315-400°C, and the discharge temperature is 420-500°C. This process adopts the method of heat extraction between sections to control the feed temperature of the rear reactor and generate medium-pressure steam for recovery. And the compression heat pump technology is used in the process, which is different from the commonly used refrigerant heat pump technology. Its efficiency is 50 ~ 90%, the use of this heat pump recovery system in the low-level heat source, to produce low-pressure steam, into the system steam pipe network.

● Proper oxyalkylene ratio and moderate reaction conditions reduce the carbon probability of the system, prolong the service life of the catalyst and improve the product selectivity.

● Butene and steam are fully fed at one time, air enters the reaction system separately, and the reaction is mild, so the water/olefin ratio can be reduced to about 8.

The application of energy-saving technology, the device energy-saving effect is remarkable. The by-product steam in the reaction stage can produce considerable economic benefits.

●For high-power electrical equipment, the appropriate turbine drive mode is selected, which also contributes greatly to energy saving.

Recommended Information

0nline message

Contact us

5/F, Block A, Building 1, Chuangyan Port, Science and Education City, Wujin District, Changzhou City, Jiangsu Province

Copyright© 2024 Ruihua Chemical