Core Technology

Core Technology

Complete process

Core Equipment

Catalyst

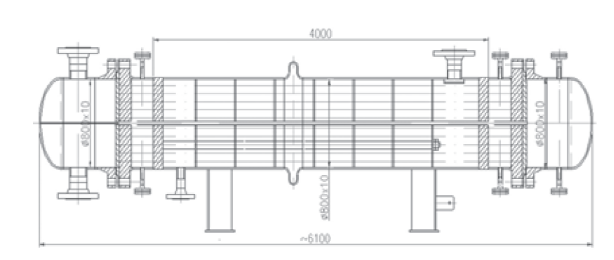

Manufacturing Technology of Double Tube Plate Heat Exchanger

Summary:

Double tube plate is a common structure in heat exchanger in recent years. In order to avoid the mixing of the two media in the tube side and the shell side to scrap the material or cause a major accident, the double tube plate structure is generally used.

Classification:

Key words:

Detailed description

Overview

Double tube plate is a common structure in heat exchanger in recent years. In order to avoid the mixing of the two media in the tube side and the shell side to scrap the material or cause a major accident, the double tube plate structure is generally used. During the hydrostatic test of the equipment, the inner tube plate leaks, which is difficult to rework and will lead to equipment rework. Therefore, the manufacturing difficulty of the heat exchanger of this structure is mainly on the expansion of the inner tube plate. In the absence of the same material and specification expansion experience, the expansion simulation test shall be conducted to determine the expansion parameters. In the process of equipment manufacturing, the processing of the tube plate must be controlled to meet the accuracy requirements of the tube hole, especially the tube hole of the inner tube plate and the expansion groove. At the same time, the polishing of the heat exchange tube, the assembly sequence of the tube bundle and other details should also be controlled. Ruikai Chemical has strictly implemented the above requirements in the manufacturing process of double-tube plate heat exchanger. The design and manufacturing tests of 1.0MPa, 2.0MPa,3.0MPa,4.0MPa and 5.0MPa double-tube plate heat exchanger samples have been completed in the test site. The materials are S31603 and S30408, and the specifications of heat exchange tubes are Φ φ25*2 and 50*3, which enable the equipment to be successfully completed and meet the needs of customers.

Key Equipment

The key equipment of the process is shown in the following table:

| Serial Number | Equipment Name | Main material of equipment | Container Category | Remarks |

| 1 | Desorption column reboiler | Q345R S32168 Ⅲ | S31603 S31603 Ⅲ | II |

| 2 | Desorber condenser | Q345R S32168 Ⅲ | S31603 S31603 Ⅲ |

Application example

The concentricity and verticality of the inner and outer tube plate holes and expansion grooves are the key points in the manufacture of double tube plate heat exchanger, while the strength expansion of the inner tube plate is the difficulty in the manufacture of double tube plate heat exchanger, and the manufacturing process should be strictly controlled. Through the efforts and exploration of process technicians and workshop workers and operators, we have accumulated experience in manufacturing double-tube plate heat exchangers. One of the equipment has been tested and verified by process samples, and the maximum pressure in the shell side can reach nearly 10MPa, which is far higher than the 5.1MP required by the drawings. Now this batch of equipment has been successfully manufactured at one time and has been operating normally.

Major customers in recent years:

| Serial Number | Project Name | Delivery time | Remarks |

| 1 |

Luoyang Refining and Chemical Jiuyuan Petrochemical Co., Ltd. n-Butane Deep Processing Industry Chain Project |

2019.11 |

Recommended Information

0nline message

Contact us

5/F, Block A, Building 1, Chuangyan Port, Science and Education City, Wujin District, Changzhou City, Jiangsu Province

Copyright© 2024 Ruihua Chemical