Core Technology

Core Technology

Complete process

Core Equipment

Catalyst

Succinic anhydride production technology

Summary:

Butanic anhydride is a widely used organic chemical raw material. Can be used for the production of vitamins, antibiotics; plant growth inhibitors, chemical intermediates and additives. Also can produce high molecular compound crosslinking agent, light stabilizer, ultraviolet absorber; preparation alkyd resin, anthraquinone dye, reinforcing fiber and so on.

Classification:

Key words:

Detailed description

market prospect

Butanic anhydride is a widely used organic chemical raw material. Can be used for the production of vitamins, antibiotics; plant growth inhibitors, chemical intermediates and additives. Also can produce high molecular compound crosslinking agent, light stabilizer, ultraviolet absorber; preparation alkyd resin, anthraquinone dye, reinforcing fiber and so on.

In particular, succinic acid can be used to synthesize PBS resin with 1,4-butanediol (BDO) as one of the raw materials for degradable plastics, which has realistic environmental significance and great development prospects.

In the context of the country's vigorous development of environmental protection industry, Ruihua has developed the technology of continuous hydrogenation of maleic anhydride to succinic anhydride. This technology can greatly reduce the production cost of succinic acid/succinic anhydride, so that many downstream products (such as PBS degradable plastics) can be more economically used and widely promoted. Contribute to environmental protection in China and open up a new path for the downstream application of maleic anhydride.

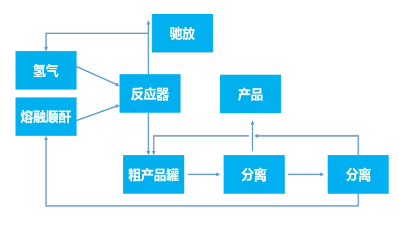

Process

The process uses molten maleic anhydride as the feed, while the proportion of quantitative hydrogen into the hydrogenation reactor hydrogenation. The crude product is passed through the separation to yield qualified products, and the incompletely separated mixture is returned to the feed section for re-feeding. The reaction off-gas is returned to the feed section by separating out qualified hydrogen.

The isothermal trickle bed reactor is designed in this process, and the means of taking heat is applied to remove the heat released by hydrogenation in time, so that the reaction can be carried out under relatively mild conditions, thus ensuring the high selectivity of the product succinic anhydride.

Ruihua Chemical independently developed a noble metal catalyst suitable for this hydrogenation process, with a maleic anhydride conversion rate of more than 50% and a succinic anhydride selectivity of 99%.

Technical advantages

●The reaction technology of maleic anhydride melt hydrogenation to succinic anhydride is simple.

● Using noble metal catalyst, it has stable high conversion and high selectivity.

The reactor used is a trickle bed reactor with heat transfer means, which can well control the reaction temperature and ensure the smooth operation of the reaction.

Due to the high melting point of the substances in the hydrogenation liquid, batch distillation is used for the fractionation and refining of the hydrogenation liquid.

● Process condensate and tail gas are fully treated, the "three wastes" emissions are reduced, and environmental pollution is controlled to a minimum.

● The purity of the product can reach more than 99.5 percent of the pharmaceutical grade. Among them, free succinic acid <0.2%, unsaturates <0.1%.

Recommended Information

0nline message

Contact us

5/F, Block A, Building 1, Chuangyan Port, Science and Education City, Wujin District, Changzhou City, Jiangsu Province

Copyright© 2024 Ruihua Chemical