Core Technology

Core Technology

Complete process

Core Equipment

Catalyst

Crystallization technology of p-xylene

Summary:

The process of crystallization separation of p-xylene is still in use now is an older process, before the emergence of adsorption separation technology, crystallization separation of p-xylene is the only technology of p-xylene refining. Due to the development of adsorption technology, the existing crystallization technology for the separation of mixed xylene of equilibrium components has no advantage, but for the separation of mixed xylene materials with high concentration of p-xylene is still attractive.

Classification:

Key words:

Detailed description

Overview

The process of crystallization separation of p-xylene is still in use now is an older process, before the emergence of adsorption separation technology, crystallization separation of p-xylene is the only technology of p-xylene refining. Due to the development of adsorption technology, the existing crystallization technology for the separation of mixed xylene of equilibrium components has no advantage, but for the separation of mixed xylene materials with high concentration of p-xylene is still attractive.

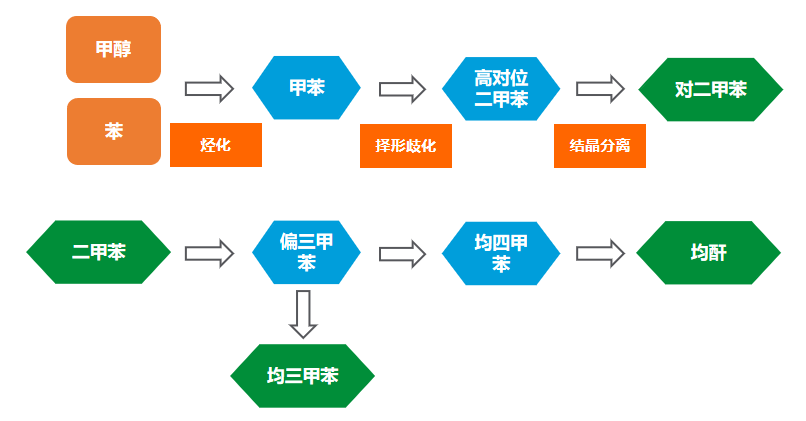

Our company has conducted in-depth research on p-xylene refining, and successfully developed a complete set of processes and engineering treatment technologies for p-xylene crystallization refining, forming unique technical characteristics.

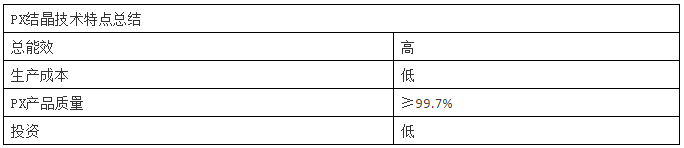

The p-xylene crystallization technology adopts a two-stage crystallization process, which is suitable for high-concentration p-xylene mixed xylene materials (including o-xylene, m-xylene, and p-xylene) PX high-efficiency and energy-saving recovery. The process reliability is high, the cost is low, the feed composition requirements are low, and the investment is lower.

Advantages of process features

01 Process characteristics: innovative crystallization process

02 process advantages: crystallization technology using two-stage crystallization process.

Features:

(1) A two-stage crystallization process is adopted, the first stage is used to ensure the purity of p-xylene, and the second stage is used to ensure the yield of p-xylene;

(2) The first-stage crystallization adopts a scraping surface type falling film crystallizer, which can effectively control the purity and particle size of the crystal and is convenient for separation;

(3) The secondary crystallizer adopts static crystallizer, intermittent operation, simple and reliable structure, and does not need to set up a low-temperature centrifuge;

(4) p-xylene product purity> 99.7%, p-xylene yield> 90%.

(5) The heat exchange network is optimized reasonably and the energy consumption of the device is reduced.

(6) The minimum requirement for p-xylene content is> 70%. If it is a balanced composition, the product can also be operated, but more energy is required.

(7) No special chemicals or adsorbents are required.

(8) small footprint.

(9) Low fixed and operating costs.

Performance characteristics

Process Description

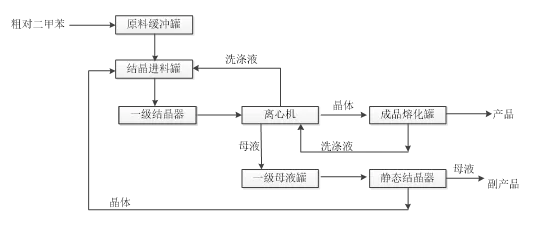

The feed is fed to a buffer tank buffer, pumped to a crystallization feed tank, and the wash liquor from the centrifuge is fed to the crystallization feed tank. The material in the tank is pumped into the primary crystallizer. Para-xylene can achieve satisfactory purity of p-xylene products through primary crystallization.

After p-xylene is crystallized in the primary crystallizer, p-xylene crystals and mother liquor flow into the centrifuge. After separation, the crystals are washed and pushed into the finished product melting tank by the centrifuge. After being heated and melted, the crystals in the tank are boosted by a pump, and then divided into two strands. One strand is sent out as a product, and the other strand is sent to a centrifuge for washing p-xylene crystals. The washed washing liquid is returned to the crystallization feed tank.

The mother liquor discharged from the centrifuge enters the primary mother liquor tank, and the mother liquor in the tank is sent to the static crystallizer for recovering p-xylene in the mother liquor. The separated mother liquor mixed xylene is used as a by-product, and the crystals are returned to the crystallization feed tank.

Recommended Information

0nline message

Contact us

5/F, Block A, Building 1, Chuangyan Port, Science and Education City, Wujin District, Changzhou City, Jiangsu Province

Copyright© 2024 Ruihua Chemical