Core Technology

Core Technology

Complete process

Core Equipment

Catalyst

Manufacture of key equipment for aromatics production technology

Summary:

Ruihua aromatics production technology can be used to produce benzene, toluene, xylene products. This technology is highly adaptable to the market, and the product plan can be adjusted according to demand, making it very competitive in small and medium-sized industrial applications.

Classification:

Key words:

Detailed description

Overview

Ruihua aromatics production technology can be used to produce benzene, toluene, xylene products. This technology is highly adaptable to the market, and the product plan can be adjusted according to demand, making it very competitive in small and medium-sized industrial applications.

The technical raw material can start from benzene, can also start from toluene. When the starting material is benzene, benzene is first alkylated with methanol to produce toluene, toluene is then disproportionated to produce high-concentration crude p-xylene and benzene, benzene is recycled, crude p-xylene is refined by crystallization, and the final products are high-purity p-xylene, mixed xylene and a small amount of C9 aromatic hydrocarbons; when the starting material is toluene, toluene is directly disproportionated to produce crude p-xylene and benzene, the product scheme is high purity p-xylene, benzene, mixed xylene and a small amount of C9 aromatic hydrocarbons.

The technology consists of two parts: benzene and methanol alkylation and toluene shape-selective disproportionation. The configuration of the alkylation and disproportionation sections can be matched according to the scale, or different ratios can be used according to the plant conditions.

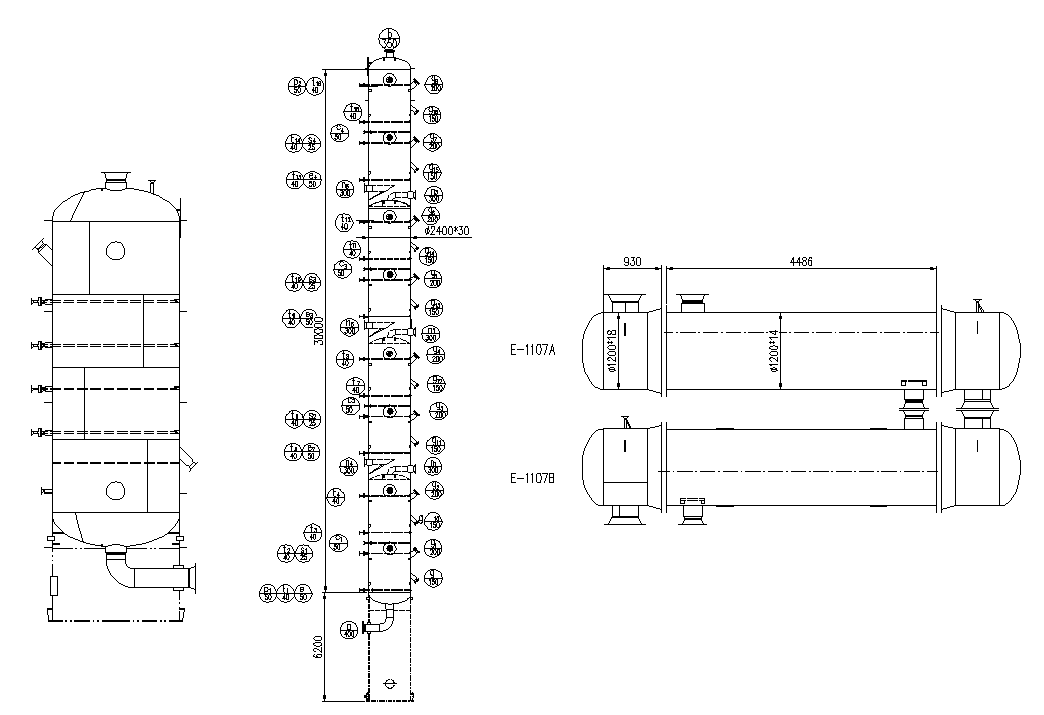

Key Equipment

The key equipment of the process is shown in the figure, as shown in the table below:

| Serial Number | Equipment Name | Main material of equipment | Container Category | Remarks | |

| 1 | disproportionation bed reactor | 15CrMoR | III | ||

| 2 | benzene heater | Q345R/16MnII/20 | II | ||

| 3 | Toluene column reboiler | Q345R/16MnII/20 | II | ||

| 4 | Inlet and outlet heat exchanger | 15CrMoR/15CrMo | II | ||

| 5 | Hydrocarbonization inlet and outlet heat exchanger | 15CrMoR/15CrMo | II | ||

| 6 | Toluene pre-evaporator | Q345R/16MnII/20 | II | ||

| 7 | alkylation reactor | 15CrMoR | III | ||

| 8 | falling film crystallizer | S30408 S30408 II | II | ||

| 9 | Finished product melting heater | Q345R,20,16Mn II | I | ||

| 10 | High pressure propylene tank | S30408 | II | ||

| 11 | Benzene feed preheater | Q345R 16MnII 20 | |||

| 12 | static crystallizer | S30408 | |||

| 13 | coarse grain melting heater | Q345R,20,16Mn II | |||

| 14 | Cold Recycler | S30408,S30408 II | Q345R,20,20 Ⅱ | ||

| 15 | Mother liquor discharge heater | S30408 | Q345R 16Mn Ⅱ | ||

| 16 | refrigerant cooler | S30408 S30408 II | |||

| 17 | Crystallization feed tank | Q345R | |||

| 18 | Methanol buffer tank | Q345R | |||

Application example

Petroleum benzene or coking benzene can be used as benzene for alkylation. Raw material methanol shall meet the requirements of GB 338-2011.

Major customers in recent years:

| Serial Number | Project Name | Delivery time | Remarks |

| 1 | Dongming CITIC Guoan Ruihua New Materials Co., Ltd. 200000 tons/year methanol to mixed aromatics unit | 2017.12 |

Recommended Information

0nline message

Contact us

5/F, Block A, Building 1, Chuangyan Port, Science and Education City, Wujin District, Changzhou City, Jiangsu Province

Copyright© 2024 Ruihua Chemical